From design to delivery

Learn more about the work we have done previously – our experience ranges from small consulting services to implementing large cost-efficient processing facilities.

Innovative Nitrate Fertilizer Production from Ammonia-Rich Wastewater

Transforming Wastewater into Resource: GMM introduces a groundbreaking approach to managing ammonia-rich wastewater from rendering plants and other industries such as biogas. Our process not only converts this wastewater into high-quality, renewable nitrate fertilizer but also produces clean, reusable water, contributing significantly to environmental sustainability.

Feasibility study for an fallen stock and risk material processing facility in Iceland

Our client approached GMM seeking to refine and advance previous evaluative and conceptual efforts, with a keen intent to align these initiatives with the current operational and economic landscape.

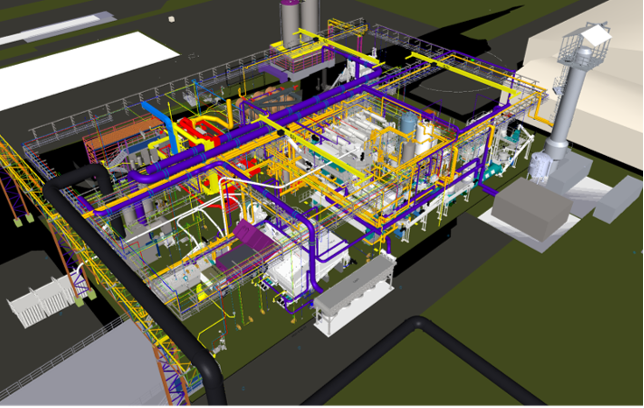

Next generation high value animal proteins production facility

Following a rigorous multi-year program of research, development, pilot studies, and exhaustive testing, GMM proudly presents its cutting-edge animal by-product processing facility to its esteemed clientele.

Sustainability consulting and reporting

GMM provides consulting services for companies in carbon footprint calculations, Life- cycle assessments, Sustainability reporting and ESG related topics according to up-to-date legislation.

Turnkey delivery of protein factory

In 2023 GMM supplied a complete modern feather processing plant for the production of high-quality feather protein for pet food and aqua feed.

Rendering plant wastewater treatment

GMM carried out conceptual planning, feasibility analysis, options mapping and project development and delivered the new facility through EPCM contract.

State-of- the-art chicken protein plant

GMM transformed a conventional risk material dry rendering facility with 40.000t/a capacity into a state-of-the-art low temperature 80.000t/a chicken protein plant in a record time.

Blood meal production plant

In smaller-scale abattoirs, the practice of allowing blood to enter drainage systems poses a significant ecological challenge. If not properly managed, this practice can lead to a considerable increase in environmental contaminants, elevating the biochemical oxygen demand of wastewater by up to ten times and tripling the levels of suspended solids.

Feasibility study and concept planning for an animal by-products processing solution in SADC

GMM undertook a thorough study commissioned by a prominent SADC meat processing company aimed at enhancing the value and profitability derived from slaughterhouse by-products, while simultaneously reducing the carbon footprint associated with these operations.

Integrated animal proteins production facility with integrated down stream functions

GMM has executed a comprehensive feasibility study with technical conceptualization, and investment estimations for a groundbreaking integrated plant specializing in processing animal by-products. The facility boasts a prodigious capacity of 360,000 metric tons per year, designed to produce high quality species-specific feed grade proteins and fats.

Integration of ABP sterilization and reprocessing system into an anaerobic digestion plant

In scenarios where animal by-product volumes are modest and economies of scale for rendering are not attainable, the most pragmatic approach may be the establishment of a versatile multi-species and multi-category processing facility.

Animal by-products collection system analysis and collection solution

GMM, in collaboration with Honkajoki Logistics, boasts a dedicated team of experts with deep specialization in the logistics of animal by-products.

This team harnesses its extensive knowledge to conduct thorough analyses and develop comprehensive nation-wide systems for the collection of animal by-products.

Feasibility Study for the Development of an Integrated Waste Management Solution

GMM recently tackled a project characterized by its exceptional demand for creative and unconventional problem-solving. The project’s complexity was heightened by extreme seasonal fluctuations in raw material volumes, presenting a challenge that required a blend of ingenuity and expertise.

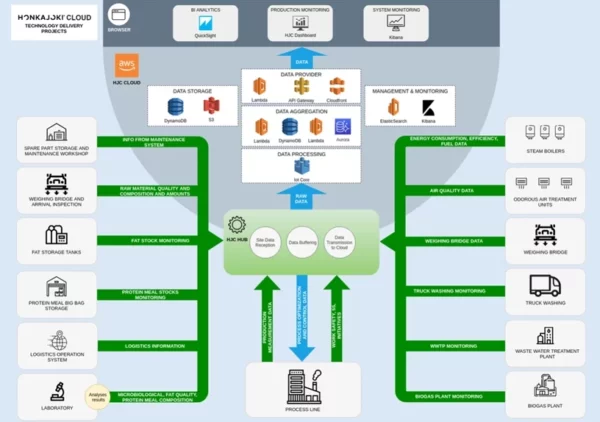

Cloud data base system

GMM has developed an AWS-cloud based architecture and processing facility data base system.

More information