Learn more about the work we have done previously – our experience ranges from small consulting services to implementing large cost-efficient processing facilities.

From design to delivery

FEATHER PLANT

Turnkey delivery of protein factory

In 2023 GMM supplied a complete modern feather processing plant for the production of high-quality feather protein for pet food and aqua feed.

A fully controllable batch hydrolysis system ensures constant high protein digestibility and gentle continuous hot air drying maintains the protein quality. The main process is supported by heat recovery, chemical and biological treatment of odorous air, and wastewater pretreatment systems.

In this project, GMM was responsible for project development and management, complete engineering, procurement, construction, training, commissioning, and plant operational support.

LTWR CHICKEN PLANT

State-of- the-art chicken protein plant

GMM transformed a conventional risk material dry rendering facility with 40.000t/a capacity into a state-of-the-art low temperature 80.000t/a chicken protein plant in a record time. With careful preparations it took merely three months from the day the old plant stopped to the day when the new production was running.

Only the building itself, HVAC system and raw material silos remained the same, everything else was changed. This became a true success story of rapidly adapting to the market changes in a capital intensive processing industry.

EPCM project

Rendering plant wastewater treatment

GMM carried out conceptual planning, feasibility analysis, options mapping and project development and delivered the new facility through EPCM contract. As the effluent composition from rendering facilities differs significantly from other wastewaters, GMM was asked to explore possible alternatives to secure the operating conditions of the facility and to reliably meet the requirements of the new tightened environmental permit conditions.

The delivered solution is flexible, reliable, and easy to maintain. It is equipped with continuous analysers and extensive remote monitoring capabilities which enables GMM specialists to provide operational support.

HonkajokiCloud

Cloud data base system

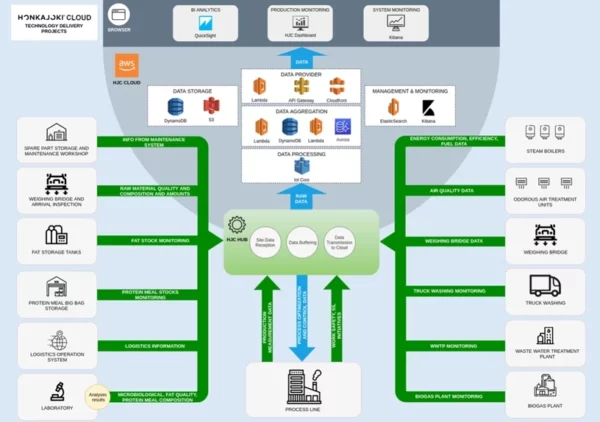

GMM has developed an AWS-cloud based architecture and processing facility data base system. This integrates the operational technology at the factory floor, logistics system, weighing bridges, laboratory analysis, energy production, product inventory and maintenance system into information technology and data aggregation tools in cloud thus creating a real time, complete delivery chain covering reporting and control system called HonkajokiCloud™.

This system offers multiple interfaces for integrating third party applications and enables the sharing of relevant data with key stakeholders. The raw and aggregated data of the whole operation is processed to show on HonkajokiCloud™ Dashboard, which is fully customizable to meet the different monitoring needs. System is capable for calculating and reporting KPIs of varying operations on Dashboard.

ESG in food industry

Sustainability consulting and reporting

GMM provides consulting services for companies in carbon footprint calculations, Life- cycle assessments, Sustainability reporting and ESG related topics according to up-to-date legislation. The evaluation of sustainability and its continuous improvement are becoming a necessity in all parts of the food chain due to evolving perspectives around the world. Emissions to land, water, and air and the overall carbon footprint resulting from industrial activity have been a important topic of public conversation in the last years. It is becoming even more critical for companies to address the gap between knowing and doing by embracing sustainable business practices.

More information